PCS® Insights

Sharing Industry Knowledge, Lessons-Learned and Published Presentations

Design of CO2 Transmission Pipeline Systems

Part 1: Hydraulics

CO2 capture and storage (CCS) will play a key role in reducing CO2 emissions. The CCS process captures carbon dioxide (CO2) from large point sources, such as fossil fuel power plants, and prevents it from entering the atmosphere. Widespread adoption of CCS will require pipelines to transport CO2 to locations where it can be stored and utilized for productive applications.

I’ve seen this trend emerge while working on three significant CO2 transmission pipeline systems in the last five years that captured CO2 from distinct sources:

• Naturally occurring CO2 source with an anthropogenic supply option

Anthropogenic CO2 coming from CCS plays by different rules than pure CO2 normally found in pipelines. Important considerations include: pipeline hydraulics, running ductile fracture mitigation and pipeline rupture dispersion modeling applying the knowledge base available at the time of design.

Hydraulics | how fluids move through pipelines

Anthropogenic CO2 sources contain impurities that cause dramatically different behavior in flow through a pipe (hydraulics) than pure CO2, whose thermodynamic properties are well known. The primary concern for the engineer here is determining an appropriate equation-of-state (EoS) relationship for the mixture, which directly affects pipeline design. Rather than using the Span and Wagner EoS generally used to model pure CO2, the Peng Robinson EoS was selected for initial design as it proves more accurate when impurities exist in the stream.

Next, a study of the effects of various impurities on the transportation of dense phase CO2 was performed in order to establish an engineering baseline to the tariff requirements for anthropogenic CO2 supply. The study builds upon published findings by P. Seevam, et al. which states that “phase properties of CO2 vary with impurities, generally increasing the two-phase region and changing the critical temperature and pressure of the mixture.” [Ref. 1]

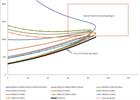

A typical pipeline operates at 1100 to 2200 psig and between 60° to 90°F. The attached figures indicate the movement of the phase envelope into this typical operating region. Of all the impurities, hydrogen shows the greatest influence on the phase envelope. For operators, this means an increase in impurities would require the minimum operating pressure be increased to a level above the phase envelope for all temperature regimes. The impact would be a reduced operating envelope and potentially additional intermediate pumping stations to maintain more consistent pipeline pressure.

Figure 1: Influence of Impurities on Phase Envelope of CO2 Fluid Mixtures

Additionally, multiple compositions were analyzed for their direct impact to transportation, i.e. pressure drop along the pipeline. For a simulated 1 mile segment of 24” OD pipeline transporting 1.0 Bscfd the pressure drop for all but one of the compositions was about 15 psi/mile. The 95% CO2; 3% N2; 2% H2 case resulted in a 32 psi/mile pressure drop.

Figure 2: Effect of Impurities on Pressure Loss in 1 mile of Pipe

To better quantify these results, a 100 mile segment of 24” OD pipeline transporting 600 mmscfd was analyzed with four (4) representative compositions. The results show the pressure drop increase nearly linear as impurities were added to the fluid.

Figure 3: Effect of Impurities on Pressure Loss Over 100 miles of Pipe

Based on these findings, it was recommended that the maximum content of nitrogen be limited to 3% and hydrogen limited to 1%. Other impurities did not have a significant impact to the performance of the fluid and therefore CO2 concentrations less than 95% could be tolerated hydraulically provided the nitrogen and hydrogen limitations are maintained.

The final impurity investigated, hydrogen sulfide (H2S) which, even in low concentrations, has a significant impact on the corrosion of the pipeline. Usually H2S occurs in such low concentrations that it has a negligible impact to pipeline operations, but unfortunately it is often found in higher concentrations in anthropogenic sources. Pipeline steels with yield strengths greater than 65,000 psi must be individually qualified to be compliant with NACE MR0175/ISO 15156 for use in sour service unless the partial pressure of H2S is maintained below 0.3 kPa (0.043 psi). For a liquid CO2 system, this translates to a maximum concentration of about 45 ppm.

A surge analysis (transient pressure analysis) was performed to better understand the extremes of the pipeline operating envelope due to compressor excursions or downstream valve closures. While the fluid stream does retain a significant amount of compressibility, sudden momentum changes from mainline valve closures can produce localized pressure spikes. The compressibility does allow the pressure transients to attenuate quickly.

Article Details

Author: Mike Istre, P.E.

Chief Engineer

PCS® Lafayette

More Information

Contact Us

We would appreciate any opportunity to assist you, and to connect you with the right person at PCS ® to address your needs and answer any questions.

Request Info Call Us 1-800-643-8306